THE BEST WAY TO MEET

THE WORLD IS WITH DOTECH

Refrigeration/AHU

Products

Refrigeration/AHU

(Extinction) SJ700 series

-Convenient use of high-performance inverter with simple adjustment

-High torque, high performance, high function inverter suitable for CRANES, EXTRUDER, LIFTS, etc.

-3-phase 200V class: 0.4~55kW / 3-phase 400v class: 0.75~400kW

Product Infomation

Easy to use, high-performance inverter with a simple adjustment

1. powerful driving achieve

- the same torque more than 200% in the notice 0.3HZ

- applicable to the lift system 0Hz sensorless vector control,

- position control

2. trip inhibition achieved stable operation

- over-current and over-voltage suppression

- deceleration of DC BUS AVR function

3. the parent device does not need to program operation function

- Simple operation sequence realized

- cranes or overdrive automatic operation suitable for the condition of the load conveyor, etc. can also

- have a parent device can be simplified, and cost savings in the space around the circuit of the control panel contributions

4. the peripheral circuits built into inverter

- noise reduction that occurs in EMC noise filter to the inverter with standard

- built-in (22kW or less) of the regenerative braking circuit (BRD)

- micro-surge voltage suppression

5. maintenance simple

- extra cooling to the removable structure fan, a smoothing capacitor, maintenance is more ease of control terminal

- design life 10 nyeon achieved by adopting a long-life components

- further extending the oN / OFF control to the service life of the cooling fan can

- condenser, aging degree, the temperature of the cooling fan and the motor of the cooling fan monitors can rise

- lifespan notice enhanced ease of maintenance by the signal

6. simple parameter setting

- data comparison functions, user-selectable features, ease of operation there are features such as the default mode

7. communications, network compatible

- RS-485 Modbus-RTU to corresponding port as standard

- option by the substrate can correspond to DeviceNet, PROFIBUS, CC-Link

- Oper Network - available

8 global response

- standards corresponding to international standards (UL, cUL, CE, C -Tick)

- sink / source logic corresponds to the standard

- width wide supply voltage specifications

9. environmental consideration

- EU RoHS Directive correspondence

- in improving environmental performance

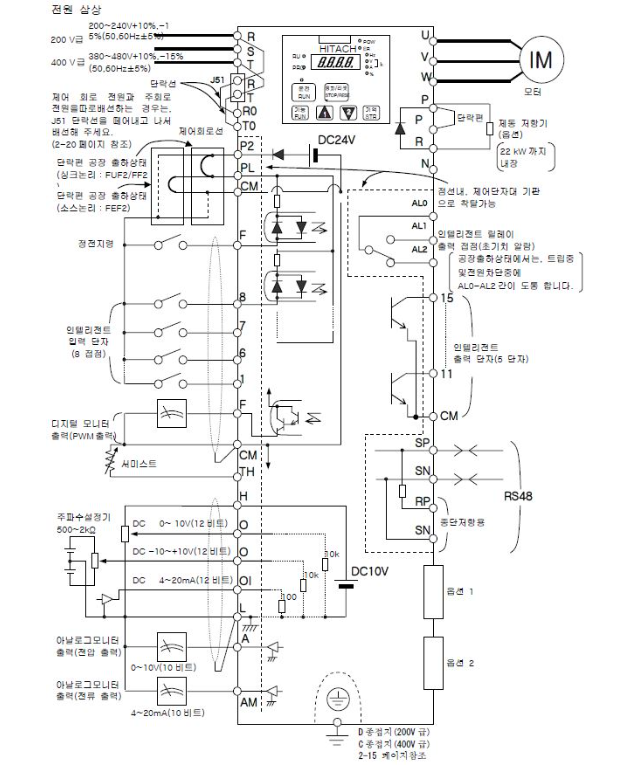

■ Diagram

■ characteristics of Hitachi low-voltage inverter

1. trip faithful suppression

- overcurrent and overvoltage suppression by high starting torque and current control, with more than 0.5 Hz 200% driven by a strong reinforcement the operation function is realized.

※ full-load operation when multiple non-inverter protection IGBT module damaged even if the output short-circuit functions employed (Hitachi patented)

2. input signal enhancement

- analog (current / voltage) to increase output monitor (AM / AMI terminal) to an emergency resolution It was equipped with a blocking function.

- Do not leave the built-in CPU (software) on the intelligent input terminals on the middle inverter output only hardware circuitry can be blocked.

3. The program operation function

- to download the program to the inverter can be simplified sequence of operation and accelerator operation can be automatic, depending on load conditions can be simplified and the host device, a peripheral circuit.

4. The peripheral circuit built into inverter

- was EMC filter and built-in video core to the AC power input, and expanded the internal model of the regenerative braking circuit (BRD).

- WJ200: full capacity, SJ700: 22Kw or less, L700: 30Kw or less

5. Micro-surge voltage suppression function

- suppresses the motor terminal voltage control pwm by Hitachi's unique approach to the control pulse 2 times or less of the DC voltage.

6. Simple maintenance

- cooling fan, simple replacement of the smoothing capacitor and the maintenance can be simple wiring without a detachable screw terminal board even more easily.

7. Life diagnostics Jobs

- was adopted to realize the long-lived component design life of 10 years, temperatures, and cooling fan motor temperature rise by the lifetime diagnostics is life warning signals such as output.

8. The improvement in environmental performance

- within the substrate part of the varnish coating, plating the copper bar to the adoption of the standard has improved environmental resistance.

9. The global response

- suited to the world standards (CE, UL, C-UL ) , and you can respond to an open network of DeviceNet, Profibus etc.

Download

- Prev

- [WJ200] WJ200 series

- Next

- [NE-S1] NE-S1 series